An FR4 PCB is the most widely used type of printed circuit board in the electronics industry. From consumer gadgets and industrial control systems to medical devices and telecommunications equipment, FR4 material has become the standard substrate for reliable and cost-effective circuit boards.

The popularity of FR4 PCB technology comes from its excellent balance of mechanical strength, electrical insulation, thermal stability, and affordability. Whether you are developing a prototype or scaling up for mass production, understanding FR4 PCBs and selecting the right FR4 PCB manufacturer is critical for long-term product performance.

What Is an FR4 PCB?

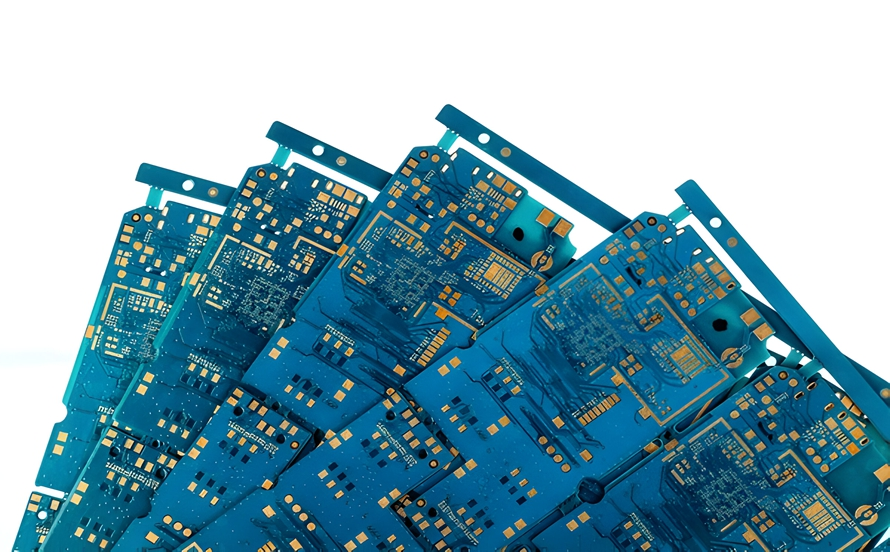

An FR4 PCB is a printed circuit board made using FR4 material as its base substrate. FR4 stands for “Flame Retardant 4,” a grade designation for glass-reinforced epoxy laminate. The material consists of woven fiberglass cloth combined with epoxy resin, providing both structural rigidity and electrical insulation.

The flame-retardant property ensures that the board can withstand high temperatures without catching fire, making it suitable for a wide range of electronic applications. Copper layers are laminated onto the FR4 substrate to form conductive traces that carry electrical signals.

FR4 PCBs are available in single-sided, double-sided, and multilayer configurations, depending on circuit complexity and design requirements.

Key Properties of FR4 PCB

One of the main reasons FR4 PCBs dominate the market is their balanced performance characteristics. The material offers excellent mechanical strength, making it resistant to bending and cracking under normal operating conditions. This durability is essential for devices exposed to vibration or mechanical stress.

FR4 also provides strong electrical insulation, preventing unwanted current leakage between conductive layers. Its dielectric properties make it suitable for most general-purpose electronic designs.

Thermal stability is another important advantage. FR4 PCBs can withstand soldering temperatures during assembly without structural damage. Standard FR4 typically has a glass transition temperature (Tg) ranging from 130°C to 180°C, while high-Tg FR4 variants are available for applications requiring better thermal resistance.

Additionally, FR4 is cost-effective compared to specialized materials such as high-frequency laminates or ceramic substrates. This makes it ideal for consumer electronics and mass-market products.

Types of FR4 PCB

FR4 PCBs come in various forms depending on application requirements. Single-sided FR4 PCBs have copper traces on one side and are commonly used in simple electronic devices. Double-sided FR4 PCBs have copper layers on both sides, allowing more complex routing and improved circuit density.

Multilayer FR4 PCBs consist of three or more copper layers stacked together with insulation layers in between. These boards are used in advanced electronics such as industrial controllers, networking devices, and embedded systems.

High-Tg FR4 PCBs are designed for environments where higher operating temperatures are expected. They provide improved reliability in automotive, industrial, and power electronics applications.

FR4 PCB Manufacturing Process

The fabrication of an FR4 PCB involves several controlled steps to ensure accuracy and reliability.

The process begins with PCB design, where engineers create circuit layouts and generate manufacturing files such as Gerber data. Once design verification is complete, copper-clad FR4 laminate sheets are prepared for processing.

For multilayer boards, inner copper layers are first imaged and etched to form circuit patterns. These layers are then stacked with prepreg sheets and laminated under heat and pressure to form a unified board structure.

After lamination, drilling machines create holes for vias and through-hole components. The holes are plated with copper to establish electrical connectivity between layers. Outer layers are then imaged and etched to complete the circuit pattern.

A solder mask layer is applied to protect copper traces from oxidation and prevent short circuits. Finally, surface finishes such as HASL, ENIG, or OSP are applied to ensure solderability during assembly.

Each FR4 PCB undergoes electrical testing to verify there are no open circuits or short circuits before shipping.

Applications of FR4 PCB

FR4 PCBs are used across nearly every sector of the electronics industry. Consumer electronics such as televisions, laptops, smartphones, and gaming devices rely heavily on FR4-based boards due to their affordability and reliability.

In industrial automation, FR4 PCBs are used in control panels, motor drivers, and programmable logic controllers. Automotive systems such as infotainment units and control modules also use high-Tg FR4 boards to withstand temperature fluctuations.

Medical equipment, telecommunications devices, power supplies, and LED lighting systems frequently incorporate FR4 PCBs because of their consistent electrical performance and mechanical durability.

Although specialized materials are required for extremely high-frequency or high-power applications, FR4 remains the preferred choice for most standard electronic products.

Advantages of FR4 PCB

FR4 PCBs offer several advantages that make them a standard in electronics manufacturing. They provide excellent mechanical stability, ensuring structural integrity during handling and assembly. Their strong electrical insulation properties reduce the risk of signal interference or short circuits.

They are also highly compatible with automated assembly processes, including surface mount technology. Their cost efficiency makes them suitable for both small-batch production and high-volume manufacturing.

Furthermore, FR4 PCBs are widely available, which ensures shorter lead times and easier sourcing compared to niche substrate materials.

Limitations of FR4 PCB

Despite its many benefits, FR4 does have limitations. For extremely high-frequency applications such as RF or microwave circuits, signal loss may be higher compared to specialized low-loss materials. In such cases, alternative laminates may be more suitable.

Similarly, very high-power or high-temperature applications may require substrates with superior thermal conductivity or higher glass transition temperatures. However, for the majority of general-purpose electronics, FR4 PCB remains the most practical solution.

How to Choose the Right FR4 PCB Manufacturer

Selecting a reliable FR4 PCB manufacturer is essential to ensure consistent product quality and on-time delivery.

A qualified manufacturer should have advanced fabrication equipment capable of handling multilayer boards, fine trace widths, and tight tolerances. Certifications such as ISO compliance and IPC standards demonstrate commitment to quality control.

Quality assurance processes, including automated optical inspection and electrical testing, are critical to minimizing defects. The manufacturer should also provide design for manufacturability feedback to improve yield and reduce production risks.

Production capacity is another key consideration. Whether you require rapid prototyping or large-scale manufacturing, your FR4 PCB manufacturer should be able to scale production without compromising quality.

Technical support and clear communication are equally important, especially when dealing with complex designs or tight deadlines.

Future Trends in FR4 PCB Technology

As electronic devices continue to evolve, FR4 PCB technology is also advancing. Manufacturers are developing improved high-Tg variants to support higher operating temperatures and enhanced reliability.

Thinner laminates and finer trace capabilities are enabling more compact and lightweight designs. Automation and smart manufacturing systems are improving consistency, reducing waste, and lowering overall production costs.

Environmental considerations are also driving innovation, with manufacturers adopting lead-free processes and eco-friendly production methods.

Conclusion

An FR4 PCB is the backbone of modern electronics, offering a reliable and cost-effective substrate for countless applications. Its excellent mechanical strength, electrical insulation, and thermal stability make it suitable for everything from consumer electronics to industrial equipment.

Choosing an experienced FR4 PCB manufacturer ensures high fabrication standards, strict quality control, and dependable delivery schedules. Whether you are developing prototypes or launching large-scale production, partnering with a professional FR4 PCB manufacturer will help you achieve consistent performance, reduced defects, and long-term product reliability.