A microwave PCB is a specialized printed circuit board designed to operate at microwave frequencies, typically ranging from 1 GHz to 30 GHz and beyond. These PCBs are engineered to handle extremely high-frequency signals with minimal loss, distortion, and interference. Unlike standard PCBs, microwave PCBs use advanced substrate materials and precise manufacturing processes to maintain signal integrity at such high frequencies.

As wireless communication, radar systems, and high-speed electronics continue to evolve, microwave PCBs have become essential components in modern electronic designs. Their ability to deliver stable and reliable performance makes them critical in applications where precision is non-negotiable.

Core Materials Used in Microwave PCBs

The performance of a microwave PCB largely depends on the materials used in its construction. Common substrate materials include PTFE-based laminates, ceramic-filled PTFE, hydrocarbon ceramic composites, and other low-loss dielectric materials. These substrates are specifically chosen for their low dielectric constant and low dissipation factor.

Copper quality and surface roughness also play an important role. Smooth copper surfaces reduce conductor loss at high frequencies, while controlled dielectric thickness ensures consistent impedance. The combination of advanced materials and precise layer construction allows microwave PCBs to perform reliably under demanding conditions.

Why Microwave PCBs Are Critical for High-Frequency Circuits

At microwave frequencies, even small variations in PCB material or layout can significantly impact performance. Microwave PCBs are designed to minimize signal attenuation, phase distortion, and electromagnetic interference. Their stable dielectric properties ensure predictable signal behavior across a wide frequency range.

Standard FR4 boards struggle to maintain consistent performance at microwave frequencies due to higher signal loss and material inconsistencies. Microwave PCBs overcome these challenges by using specialized materials and tight manufacturing tolerances, enabling engineers to design circuits with confidence.

Key Advantages of Microwave PCB Technology

One of the main advantages of microwave PCBs is excellent signal integrity. Low-loss substrates help preserve signal strength and reduce noise, which is crucial for high-frequency and high-speed applications.

Microwave PCBs also offer superior thermal stability, allowing them to operate reliably in environments with fluctuating temperatures. Their mechanical stability and resistance to moisture and chemicals further enhance durability. These benefits make microwave PCBs suitable for long-term use in mission-critical systems.

Additionally, microwave PCBs support complex multilayer designs, enabling compact and high-density layouts without compromising performance.

Typical Applications of Microwave PCBs

Microwave PCBs are widely used in wireless communication systems, including base stations, antennas, and RF modules. They are essential for ensuring efficient signal transmission in 5G networks and other advanced communication technologies.

In aerospace and defense, microwave PCBs play a vital role in radar systems, navigation equipment, and satellite communications. Their reliability and precision are crucial for maintaining accurate signal processing in demanding environments.

Other applications include automotive radar systems, medical imaging equipment, test and measurement instruments, and high-speed data transmission systems. Wherever high-frequency performance is required, microwave PCBs are a core component.

Microwave PCB vs Standard PCB

The difference between a microwave PCB and a standard PCB lies primarily in performance and material selection. Standard PCBs, typically made from FR4, are suitable for low- to mid-frequency applications but suffer from high signal loss at microwave frequencies.

Microwave PCBs are specifically designed to handle high-frequency signals with minimal loss and consistent impedance. While they are generally more expensive than standard PCBs, their performance advantages justify the investment in applications where accuracy and reliability are critical.

Designers often choose microwave PCBs when signal integrity, low noise, and precise frequency control are essential to product success.

Design Considerations for Microwave PCBs

Designing a microwave PCB requires careful attention to layout, impedance control, and grounding. Trace width, spacing, and stack-up configuration must be precisely calculated to maintain consistent impedance across the board.

Component placement is another important factor. Sensitive RF components should be positioned to minimize signal path length and reduce interference. Proper grounding and shielding techniques help prevent signal leakage and crosstalk.

Collaboration with an experienced manufacturer during the design phase ensures that the PCB layout is optimized for both performance and manufacturability.

Manufacturing Challenges in Microwave PCBs

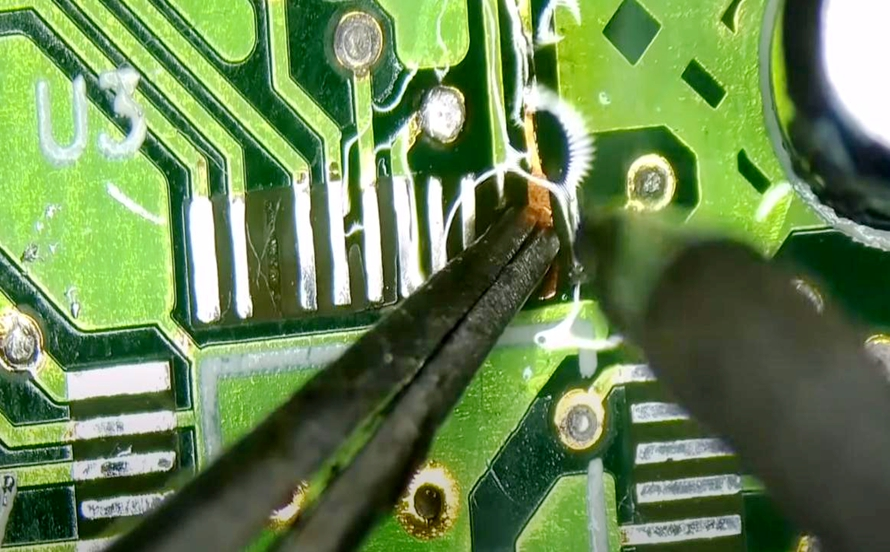

Manufacturing microwave PCBs involves specialized processes and strict quality control. Handling low-loss materials such as PTFE requires advanced equipment and expertise. Achieving precise drilling, etching, and layer alignment is critical to maintaining electrical performance.

Surface finishes, copper bonding, and lamination processes must be carefully controlled to prevent defects. Comprehensive testing, including impedance testing and high-frequency performance verification, is essential to ensure consistency and reliability.

Due to these complexities, microwave PCB production demands a higher level of technical capability compared to standard PCB manufacturing.

Choosing the Right Microwave PCB Manufacturer

Selecting the right microwave PCB manufacturer is a key factor in project success. A qualified manufacturer should have extensive experience with high-frequency materials and RF PCB fabrication.

Look for a manufacturer that offers design support, advanced testing capabilities, and strict quality assurance processes. Compliance with international standards and a proven track record in microwave PCB production are strong indicators of reliability.

An experienced manufacturing partner can help optimize your design, reduce production risks, and ensure consistent quality from prototyping to mass production.

Final Thoughts

Microwave PCBs are essential for high-frequency electronic systems that demand precision, reliability, and superior signal performance. With advanced materials, careful design, and specialized manufacturing processes, these PCBs enable the next generation of wireless communication, radar, and high-speed technologies.

If you are developing high-frequency applications and need consistent, high-quality results, partnering with a trusted microwave pcb manufacturer is crucial. The right manufacturer will help turn your design into a reliable, production-ready solution that meets the strict demands of modern microwave electronics.